Biobased decor, circular by design.

In everything I create, I seek the balance between stylish design and sustainable production. That's why I choose recycled PLA at the core of my creations.

Why I use recycled materials

rPLA has a lower climate impact compared to fossil-based plastics, reducing dependence on non-renewable resources. By choosing recycled materials, I want to reduce the need for (new) virgin resources, which reduces environmental impact and supports circular production.

It is available in interesting finishes such as matte, glossy and transparent, with an extensive color palette that makes it perfect for creating distinctive design objects.

What is rPLA?

rPLA stands for recycled PLA. PLA itself, or polylactic acid, is a special type of bioplastic.

It is made from renewable, plant-based sources such as corn starch, unlike traditional plastics that are often made from petroleum.

PLA is a thermoplastic, which means it softens when heated and hardens when cooled, making it very suitable for 3D printing.

rPLA is a recycled version of PLA, derived from packaging waste.

Where does it come from?

The rPLA I use is made from post-industrial recycled (PIR) sources from the Benelux and other EU-countries.

PIR refers to plastic that is discarded during production processes and does not reach the end consumer. Think of packaging materials (vegetable or fruit containers and cups), agricultural waste, textiles, and so on.

This type of post-industrial plastic is typically of very good quality and clean, which makes it easier to process.

How is it made?

PIR plastic is converted into granulate through mechanical recycling, without chemicals, making it more sustainable and efficient.

This process includes sorting, cleaning, grinding, and melting the plastic and is performed by a recycling specialist in the EU.

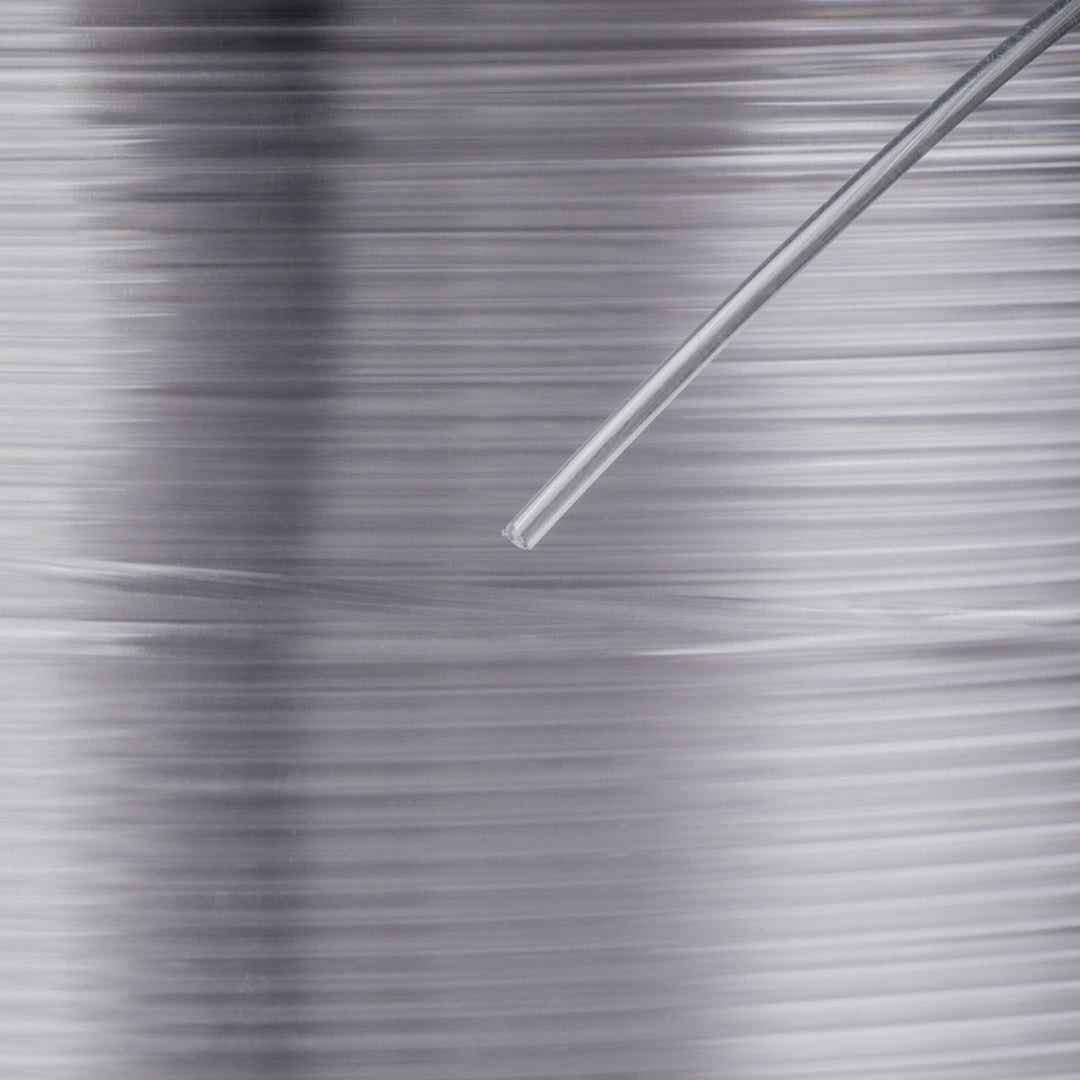

When granulated, Colorfabb (NL) uses this as the basis for their rPLA filament, processing it through extrusion lines that wind the filament thread onto a spool, so I can use it for my creations.

"With rPLA, I transform what others discard as waste into something unique for your home."

Erwin Boxen

Founder of Slimprint